Silicone fiberglass fabric is one kind of high-performance and multi-purpose compound material that ...

.jpg?ver=1.2?imageView2/2/w/500/h/500/format/jpg/q/100)

.jpg?ver=1.2?imageView2/2/w/500/h/500/format/jpg/q/100)

Silicone fiberglass fabric is one kind of high-performance and multi-purpose compound material that ...

Silicone Insulation Fabric Thermal insulation: Silicone insulation fabric is the current high-grade...

Product principle: Fire blanket is not burned with open fire : This is the wrong understanding that...

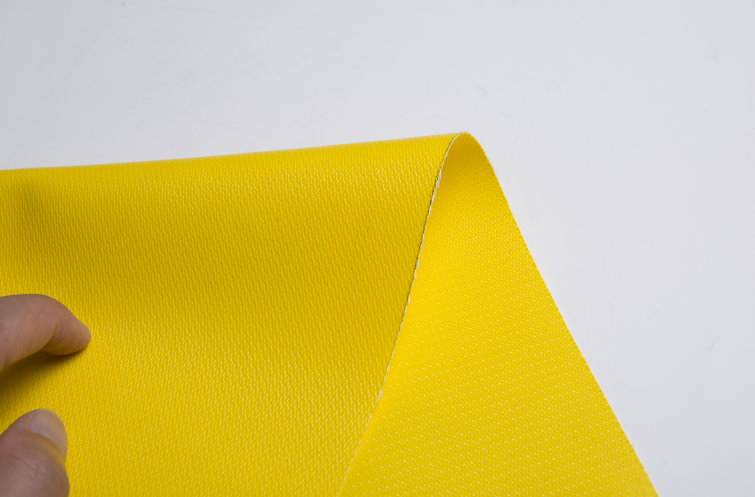

Silicone Coated Fiberglass Tarpaulin Silicone fiberglass fabric is one kind of high-performance and...

Silicone Conveyor BeltFeatures: I. Material: special silicone material for conveyor belt, toughnes...

Decoration Membrane Features: 1. High fire rating, for the national A1 standard. 2. Good light trans...

Silicone Insulation FabricFeatures:I. Silicone coating process: internal and external double-layer ...

Fire blanket is also named fire blanket, fire blanket, escape blanket, etc. It is made of glass fibe...

Silicone Coated Fiberglass Tarpaulin Silicone fiberglass fabric is one kind of high-performance and...

Decoration Membrane Applicable places: places with high requirements for lighting fire prevention, p...

White Phosphorus Bomb FabricWhite Phosphorus Bomb Fabric is made of silicone coated fiberglass fabr...

White Phosphorus Bomb Protected FabricWhite Phosphorus Bomb Protected Fabric is made of silicone co...

Silicone coated fiberglass fabric is a versatile and high-performance material t...

View MorePVC coated fiberglass cloth is a high-performance composite material that combin...

View MorePTFE (polytetrafluoroethylene) glass fiber cloth is a high-performance composite...

View MorePVC Coated Tarpaulin Fiberglass Fabric plays a variety of important roles in the...

View MorePVC coated tarpaulin has become the material of choice for multiple industries d...

View MoreIf you are interested in our products or have any questions, please consult us.